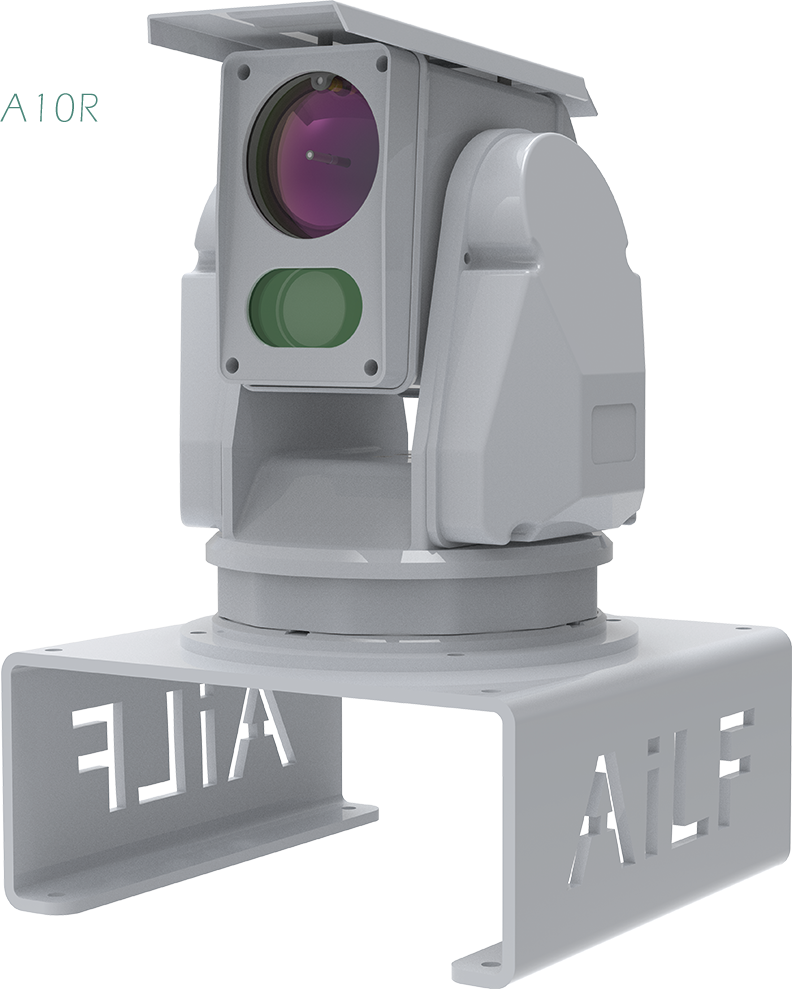

A10R Vehicle-Mounted Overhead Laser Methane Leakage Inspection System

A10I Vehicle-Mounted Front Laser Methane Leak age Inspection System

A10IE Vehicle-Mounted Front Laser Methane Leakage Inspection System (including Ethane

Identification)

![]()

A10R is equipped with the omnidirectional cloud pla-

tform integrated camera and highperformance laser s-

ensor, applicable to the leakage inspection for pipelines

under sidewalk and greenbelt. The high-position insta-

llation on vehicle roof can avoid the inspection raybeing

blocked and reduce the false alarm.

A10R is response speed is as high as 0.025 s

With the cooperation of quick response algorithm, it e-

nables the equipment to rapidly adjust to the fast-chan-

ging reflecting materials in the course of vehicle movin-

g, and capture the leaking gas more efficiently.

Cloud platform motion control applies the motor - enc-

oder closed-loop structure with a self-stabilization func-

tion,ensuring a precise directivity on a bumpy road surf-

ace; Rotationand video are interconnect, cloud platform

can automatically calculate the rotation angleto aim at

target only if clicking on the screen of inspection termi-

nal.

Equipped with AlphaOne intelligent inspection terminal, you can control

the cloud platform position by a Tablet PC with the inspection track aut-

omatically recorded; Events e. g. leaking point, digging damage etc. can

be recorded; overhead and front leakage inspection and ethane identifi-

cation function are integrated in one set of system; Inspection report can

be produced and uploaded.

A10I can absorb the surrounding air into vehicle’s inn-

er inspection chamber for analysis, and extract the infor-

mation for tiny amount of methane concentration. It is

applicable to identifying the floating gas of tiny leakage

with a mutual complement for the overhead system.

A10I is static detection limit is as low as 0.5 ppm

The unique high-reliability laser chamber multiple reflec-

tion detection technology applies the long path to bring

high sensitivity while effectively controlling the chamber

volume, reducing the delay and dilution effect; The abs-

orptiontank is simple to maintain and clean due to its

"easy disassembly and cleaning"technology.

A10IE integrates the laser ethane identification function,

by which it can rapidly judge andconfirm whether any n-

atural gas in case of identifying leakage without conduc-

ting the secondary sampling analysis.

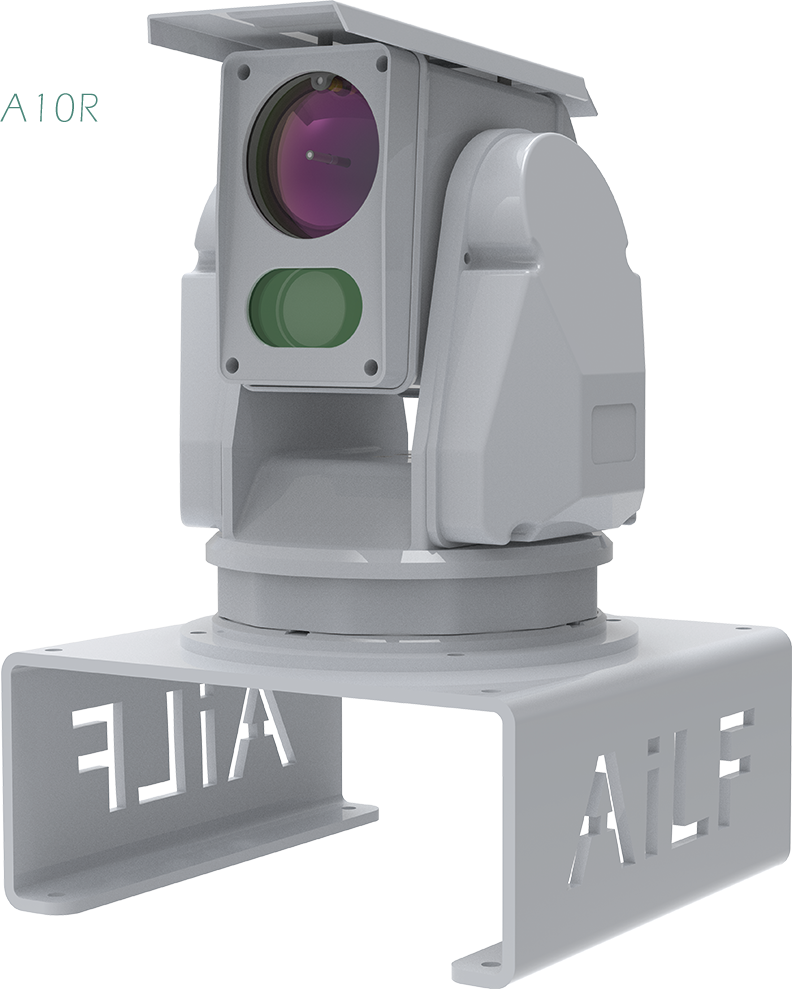

A10R Vehicle-Mounted Overhead Laser Methane Leakage Inspection System

A10I Vehicle-Mounted Front Laser Methane Leak age Inspection System

A10IE Vehicle-Mounted Front Laser Methane Leakage Inspection System (including Ethane Identification)

![]()

A10R is equipped with the omnidirectional cloud platform integrated camera and highperformance laser sensor, applicable to the leakage inspection for pipelines under sidewalk and greenbelt. The high-position installation on vehicle roof can avoid the inspection raybeing blocked and reduce the false alarm.

A10R is response speed is as high as 0.025s

With the cooperation of quick response algorithm, it enables the equipment to rapidly adjust to the fast-changing reflecting materials in the course of vehicle moving, and capture the leaking gas more efficiently.

Cloud platform motion control applies the motor-encoder closed-loop structure with a self-stabilization function,ensuring a precise directivity on a bumpy road surface; Rotationand video are interconnect, cloud platform can automatically calculate the rotation angleto aim at target only if clicking on the screen of inspection terminal.

Equipped with AlphaOne intelligent inspection terminal, you can control the cloud platform position by a Tablet PC with the inspection track automatically recorded; Events e.g. leaking point, digging damage etc. can be recorded; overhead and front leakage inspection and ethane identification function are integrated in one set of system; Inspection report can be produced and uploaded.

A10I can absorb the surrounding air into vehicle’s inner inspection chamber for analysis, and extract the information for tiny amount of methane concentration. It is applicable to identifying the floating gas of tiny leakage with a mutual complement for the overhead system.

A10I is static detection limit is as low as 0.5 ppmThe unique high-reliability laser chamber multiple reflection detection technology applies the long path to bring high sensitivity while effectively controlling the chamber volume, reducing the delay and dilution effect; The absorptiontank is simple to maintain and clean due to its "easy disassembly and cleaning"technology.

A10IE integrates the laser ethane identification function, by which it can rapidly judge andconfirm whether any natural gas in case of identifying leakage without conducting the secondary sampling analysis.